The mmepụta usoro nke gbanwetụrụ plastic ahụ tumadi gụnyere: Ịgwakọta usoro, extrusion usoro, nkwakọ.

1. Nnwale isii nke ịgwakọta: ịgba ụgwọ, ịnata, ihicha, nkewa, ịkụgharị, ịgwakọta.

2. Nchacha igwe: a na-ekewa ya na akara anọ A, B, C na D, nke An bụ nke kachasị elu (elu ala dị nro), na ihe ndị ọzọ.

3. Ịkekọrịta ihe: hụ na akụrụngwa ndị dị mkpa agaghị ezighi ezi na arụ ọrụ ahụ.

4. Ịgwakọta: usoro nke nchịkọta izugbe bụ: ntụ ntụ ntụ, toner.

ⅡNri.

Site na njikwa kọmputa, a na-achịkwa oghere dị ka mgbanwe dị arọ si dị.

Uru:

1. Gbaa mbọ hụ izi ezi nke oke ihe.

2. Belata delamination nke ihe.

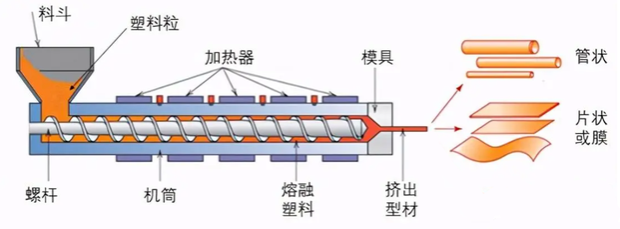

Ⅲ.Ịghasa plasticizing, extrusion, ịbịaru.

Ⅲ.Ịghasa plasticizing, extrusion, ịbịaru.

ⅣMmiri jụrụ oyi (sink).

Jụụ na ajụkwa ihe nkedo rọba ewepụ site na extruder.

ⅤIkuku ikuku (mgbapụta mmiri, mma ikuku).

Wepu mmiri dị na mpempe plastik wee kpoo ya.

Ⅵ.granulation.

N'ozuzu, size nke ịkpụ ahụ bụ 3mm * 3mm PVC ihe ọkọlọtọ ọkọlọtọ: GB / T8815-2002.

Ⅶ.Sifting (ihuenyo na-ama jijiji).

Nzacha ihe ndị a na-egbutu ma na-achịkwa nha nke ihe ndị ahụ.

Ⅷ.Overmagnetization (ihe nzacha magnetik).

Wepụta irighiri ihe ndị nwere adịghị ígwè.

Ⅸ.Nyocha na saịtị.

Ọ bụ tumadi njikwa ọdịdị, nke na-achọpụta ma agba nke ihe ndị ahụ ruru ọkọlọtọ na ma ọ dị n'otu.

Ⅹ.Ngwakọta (cone rotary igwekota okpukpu abụọ).

Gbaa mbọ hụ na agba na arụmọrụ nke ihe ahụ plastik emezigharịrị bụ otu.

ⅪNkwakọ ngwaahịa (igwe ihe nkwakọba ihe niile nke elektrọnik).

Ⅻ.Nchekwa

Oge nzipu: 23-12-22