Usoro imepụta ọkọlọtọ na-agụnye: Mixụkọta usoro, usoro nkwakọ.

1. Nnwale isii nke ịgwakọta: Billgba ụgwọ, ịnata, nhicha, nke na-esi na-esi, na-agwakọta.

2. Nhichaji igwe: E kewara ya na akara ule anọ a, b, c na d, nke a bụ nke kacha elu (na dị larịị), na nke dị larịị), na nke dị larịị), na nke dị larịị), na nke dị larịị), na nke dị larịị), na nke dị larịị).

3

4. Gwakọta: Usoro nke agwakọta General bụ: ntụ ntụ ntụ ntụ, toner.

Ⅱ. Nri.

Site na nchịkwa kọmputa, a na-achịkwa oghere dị ka mgbanwe ibu.

Uru:

1. Gbaa mbọ hụ na izi ezi nke ihe.

2. Belata obere ihe.

Ⅳ. Mmiri jụrụ (sink).

Jụụ ma dị jụụ mpempe akwụkwọ plastik wepụtara site na onye na-eweta ya.

Ⅴ. Ihicha ikuku (mmiri mmiri, mma ikuku).

Wepu mmiri site na mpempe plastic ma kpoo ya.

Ⅵ. Granilation.

N'ozuzu, nha ibe ahụ bụ 3mm * 3MM PVC PROM: GB / T8815-2.

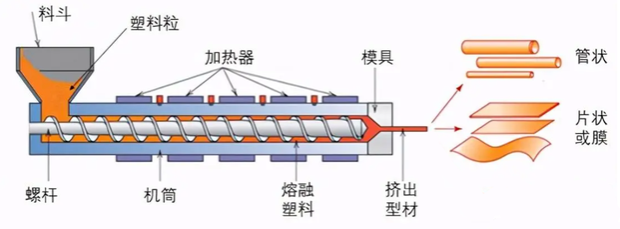

Ⅶ. Na-agbatị (ihuenyo na-efegharị).

Choputa ya na ibe ya ma na-ejikwa nha nke ahu.

Ⅷ. Ihe overmagnetnet (nzacha).

Na-a abusụ ndị na-eme mkpọtụ.

Ⅸ. Nnyocha saịtị.

Ọ bụ ya bụ njikwa ọdịdị, nke na-achọpụta ma ụcha ahụ dịịrị ọkọlọtọ ma ma ọ dị n'otu.

Ⅹ. Mixgwakọta (ma ọ bụ abụọ conte breakmary).

Gbaa mbọ hụ na agba na arụmọrụ nke ihe ndị na-agbanwe agbanwe.

Ⅺ. Nkwakọ ngwaahịa (igwe na-ejikọ igwe eji arụ ọrụ).

Ⅻ. Storaji

Oge post: 23-12-22