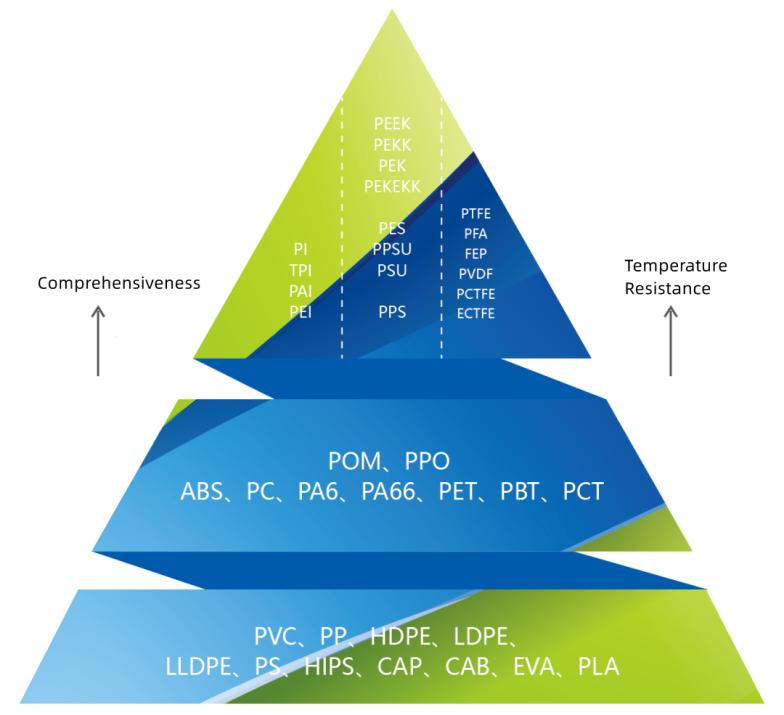

N'afọ ndị na-adịbeghị anya, itinye akwụkwọ nke injinịa pụrụ iche na-eji nwayọọ nwayọọ gbatịkwuru ndị agha na mpaghara ndị nkịtị, dị ka ụgbọala, na-ebubata ngwa ahịa. N'etiti ha, polyphenene sulfide (PPS) na polletathetone (Peek) bụ ụdị plastik na ngwa ngwa pụrụ iche na ngwa ngwa dịtụ.

Peek dị elu karịa PPS na usoro nke ike, ike na oke ọrụ na-arụ ọrụ kachasị. N'ihe banyere oke okpomọkụ, nguzogide ọnọdụ pek bụ ihe dị ka 50 Celsius C dị elu karịa nke pps. N'aka nke ọzọ, uru dịtụ ọnụ ahịa na arụmọrụ nhazi nke PPS na-eji ya mee ihe n'ọtụtụ ebe.

PPS nwere uru arụmọrụ ndị a:

(1) Intrisic Flament

Different from PC and PA, PPS pure resin and its glass fiber/mineral powder filled composites can easily achieve V-0 @ 0.8mm or even thinner thickness V-0 flame retardant without adding any flame retardant level. Although PC and PA have cheaper prices and better mechanical strength (especially impact strength) than PPS, the cost of PC and PA composites with halogen-free flame retardant formulations (V-0@0.8mm level) is higher than that of PPS. It will rise sharply, and in many cases even higher than PPS materials with the same mechanical strength.

(2) Ultra-High Live Live

Na mpaghara ngwa ndetu, uru a pụtara ìhè karịa PC. Ihe mgbakwunye dị elu agaghị emetụta ihe siri ike nke ihe ahụ ma na-akpata nsogbu ịhazi, kamakwa ọ na-akpata nsogbu dị ka eriri dị iche iche, nnukwu warage, na njikwa arụ ọrụ. Maka pps nke ọkara nke ọkara, oke mmiri ya na-enye ohere iko iko na-ejupụta na mfe gafere 50%. N'otu oge ahụ, na usoro nke okpomoku okpomoku gbazee na ntughari, ala nke PPs nwere ike ime ka udiri ahihia nke di elu na ntughari nke ikpe azu na-abawanye modulu.

(3) Ultra-obere mmiri

Uru a bụ nke PA. N'ihe banyere imeju afọ, pa na pps jupụtara na pps dị ka atụnyere; Maka akụrụngwa akụrụngwa, PA Comsites na otu ego ole ka ha nwere. Ihe si na ya pụta bụ na ọnụego ọnụego PPS n'ihi oke nrụrụ mmiri dị ala karịa nke ngwaahịa Pal.

(4) udiri ihe eji eme ihe ma di elu

Site na njikọta nke Ebuldị pụrụ iche na mkpokọta ọnọdụ okpomọkụ, PPỌ PPS na-emekwa ka ihe dị ka enyo mmadụ, na elu ga-adịcha mma dị ka enyo.

Peek nwere ihe ndị a dị ịrịba ama:

(1) nnukwu okpomọkụ egusi eguzogide.

Enwere ike iji ya ruo ogologo oge na 250 Celsius C, ọnọdụ okpomọkụ pụrụ iru 300 Celsius C n'otu ntabi anya, ọ na-emetụtakwa ya na obere oge na 400 Celsius.

(2) Njirimara eji arụ ọrụ dị mma na nkwụsi ike.

Peek nwere ike ịnọgide na-enwe ike dị elu na oke okpomọkụ. Ike na-agwụ ike na 200 Celsius C nwere ike iru 24, yana ike na-agba mbọ na ike ike na 250 Celsius C nwere ike iru 12-13 MPA. Ọ dị mma maka ịmepụta ngwaahịa na-aga n'ihu na okpomọkụ dị elu. ihe ndị na-arụ ọrụ. Peek nwere oke isi ike, nguzosi ike dị mma na ọnụọgụ dị ala nke mgbasawanye nke Loodion, nke dị nso na aluminom ọla. Na mgbakwunye, Peek nwekwara ezigbo nguzogide na-eguzogide na-emegide ya n'oge ọrụ, ọ gaghị eweta ndọtị dị ukwuu n'ihi ndọtị oge.

(3) ezigbo kemịkal.

Peek na-emegide ọtụtụ kemịkal nke ọma, ọbụlagodi na oke okpomọkụ, yana iguzogide corrosion yiri nickel nchara. N'ọnọdụ nkịtị, naanị ihe nwere ike igbari peek bụ culfuric acid.

(4) Ezigbo hydrolysis iguzogide nguzogide.

Na-eguzogide ọgwụ na-eme ka mmiri ma ọ bụ mmiri dị elu. N'okpuru ọnọdụ okpomọkụ na nrụgide dị elu, ihe ndị ọzọ nwere ike ịrụ ọrụ na mpaghara mmiri ma nọgide na-enwe ezigbo ọrụ arụ ọrụ. Dị ka oke mmiri na-aga n'ihu na 100 Celsius C ruo ụbọchị 200, ike na-agbanwe agbanwe.

(5) ezigbo ire ere.

Ọ nwere ike iru ọkwa Ul 94 V-0, na-emenye onwe ya, ma na-apụta anwụrụ ọkụ na anụ na-egbu egbu na-eme ka ikuku na-egbu egbu.

(6) ezigbo eletrik arụmọrụ.

Peek na-ejigide ihe elektriki n'elu otu ugboro na oke okpomọkụ.

(7) nguzosi ike siri ike.

Peek nwere ihe owuwu nke ọma, yana akụkụ ndị pere mpe nwere ike rụọ ọrụ nke ọma n'okpuru oke doses nke ionizing radieshon.

(8) ezigbo isi ike.

Ike ọgwụgwụ iguzogide nrụgide ọzọ bụ plastik niile ma na-atụnyere alloys.

(9) Mkparị dị ukwuu ma yie nguzogide.

A na-edozikwa nguzogide na ala dị ala nke esemokwu a na-edobe na 250 Celsius.

(10) ezigbo nhazi arụmọrụ.

Iwepu nsị na ịkpụ akpụ akpụ, yana arụmọrụ dị elu.

Oge post: 01-09-22